|

|

|

| |

OPTIONAL

EQUIPMENT

Automactic Damper System

|

The microprocessor controller is the main controller

of the system, responsible for time, temperature

and atmosphere of a kiln firing. It reads the temperature

by means of a thermocouple mounted on the back wall

protruding into the interior of the kiln. The microprocessor

then processes the pre-programmed parameters (i.e.:

ramp soak segments) and adjusts the output signal

to the proportioning valve located on the valve

train. Depending on the call for heat from the microprocessor,

the proportioning valve will vary the amount of

gas reaching the burners. The kiln is also equipped

with an oxygen probe located just below the thermocouple.

Reading the atmosphere of the kiln via the oxygen

probe, the microprocessor sends a signal to the

damper motor which then adjusts the damper automatically

to control the atmosphere.

By programming the microprocessor's parameters with

time and temperature, the kiln can be fired by ramping

to a set point within a particular time frame. This

ramp time plus a soak time is one segment. The microprocessor

contains four ramp soak segments making up what

is called a firing profile. This profile is stored

in the microprocessor's nonvolatile memory. The

microprocessor contains two operating modes, AUTO

and MANUAL. These pre-programmed firing profiles

can be operated by the AUTO mode. The kiln can also

be fired manually by the microprocessor controller.

|

|

Our auto-damper system is PC controlled using a

windows based program that is very easy to operate

and hook up. All the parameters from the controller

are displayed on your computer screen, making it

easier to update and change your firing profiles.

The program takes about 5 megabytes of space on

your hard disk. There are no major upgrades needed

for you to install and connect the microprocessor

program. The microprocessor program offers remote

station firing capabilities.

|

|

Automatic damper controls

the kiln's atmosphere |

|

|

The oxygen probe on

the kiln sends atmosphere conditions

to the control panel. The microprocessor

reads the signal and adjust the damper

automatically. |

|

|

|

The proportional gas

valve maintains just the right amount

of gas to ramp or soak the kiln at all

times during the firing. |

|

|

|

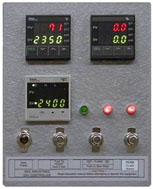

Microprocessors on the

kiln control both temperature (ramp/soak)

and atmosphere. |

|

|

|

The microprocessor controller is

equipped with a high-limit alarm. The high-limit

alarm will shut the kiln down once the kiln hits

the high limit temperature. The damper is automatically

closed to prevent any thermal shock. lf there is

any disruption of gas or flame failure, the flame

safety system will automatically shut the kiln down.

Our auto-damper system is backed by an ETL Intertek

(Canadian Standard Association) certification, meeting

the required safety standards for gas appliances.

|

|

|

| |

A thermocouple

is a temperature reading device made up of two dissimilar

metals that, when heated, produce a thermoelectric

current. The speed of the current increases as the

temperature increases.

|

|

|

|

|

|

|