|

|

|

| Geil's

Innovative Downdraft Firing System

|

|

The

original GEIL Downdraft Design was created in 1971

by owner, Paul H. Geil, and has since been refined

and improved upon without alteration to the basic

design.

The basic design features: |

-

Elimination

of all deflection devices characteristic

of other kiln designs

-

Multi-directional

downdraft circulation

-

High

velocity, natural draft, Venturi burners

-

Precise

atmosphere control

-

Even

temperature distribution throughout the

kiln chamber

|

|

The

GEIL Downdraft Patented Design differentiates itself

from other kiln designs with its unique placement

of the burners in relation to the draft.

|

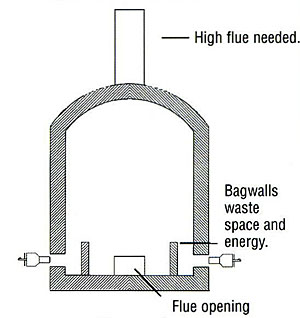

Standard

Downdraft Kilns

The standard

relation of the burners to a downdraft-type system

utilizes a horizontal placement of the burners,

thereby necessitating the use of deflection devices,

such as bagwalls, to deflect the heat flow upward.

This deflection drastically reduces the velocity

at which the heat enters the chamber, therefore

a high flue is necessary in order to pull the atmosphere

through the kiln. (figure 1) |

|

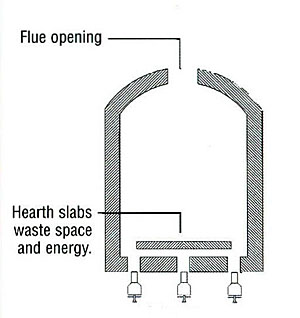

Standard

Updraft Kilns

The vertical placement of the burners commonly found

in updraft design requires the deflection of heat

energy outward and upward through the use of hearth

slabs.

The updraft kiln has the flue opening at the top

of the kiln and does not pull the atmosphere down

through the center. The heat travels in only one

direction-up and out the flue. This produces very

little circulation and wastes valuable heat energy.

(figure 2) |

| Standard

Downdraft Kilns

Figure

1

Front view cutaway |

|

|

|

| Standard

Updraft Kilns

Figure

2

Front view cutaway |

|

|

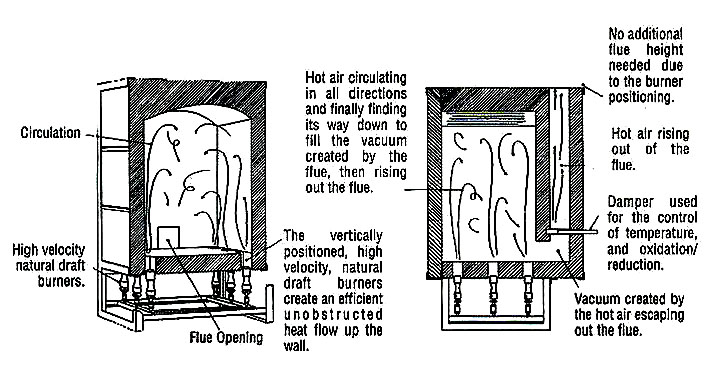

| The

Geil Downdraft design

The GEIL Downdraft System utilizes heat energy to

its fullest potential through recirculation. This,

of course, means energy savings and consistently

superior results in firing. In contrast to other

kiln designs the GEIL Design ingeniously allows

for the elimination of all such deflection devices

through the vertical positioning of the burners

within the framework of a downdraft design. (figure

3)

Deflection devices simply absorb valuable heat energy

and obstruct the direct transfer of heat to the

setting. The elimination of deflection devices produces

an unobstructed, multi-directional heat flow or

circulation within the kiln chamber which conserves

fuel, produces excellent firing results and offers

more available combustion area.

Combustion areas running the entire length of the

side walls insure a proper oxygen to gas ratio,

necessary for complete combustion to occur. The

occurrence of combustion heats the kiln's atmosphere.

The kiln's heated atmosphere rises and is drawn

downward by the action of the flue. The flue opening

is centered in the rear wall directly over the kiln

floor and serves to create the necessary vacuum

to pull the atmosphere downward through the setting.

Precise atmosphere distributions are easily achieved

through the adjustment of the damper and the main

gas valve controlling the burners. |

| The

Geil Downdraft design

Figure

3

Front view cutaway

|

|

|

|

|

|

|

|

|