|

|

|

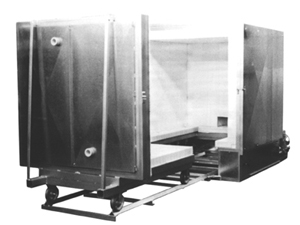

| Fiber

Lined Shuttle Kilns

|

GEIL

Natural Draft Kilns

All GEIL Shuttle Kilns are constructed with

the same solid steel construction as our front-loading

models. Heavy duty V-grooved steel casters

are used on the car portion of the kiln, enabling

the car to roll freely on angle iron tracks.

The fiber construction method is also identical

to that of our front-loading models.

The two-car Shuttle Kiln has long been known

for its high production capabilities. While

one car load is being fired, the other car

may be simultaneously loaded or unloaded,

preparing for the next firing cycle. This

conserves time and increases production considerably.

The major advantage of a car-type construction

is the ease of loading and unloading. A Shuttle

Kiln curtails strenuous and often cumbersome

loading and unloading, characteristic of larger,

front-loading units. Additionally, Shuttle

Kilns offer the added advantage of loading

and unloading from both sides. |

|

Fiber

Lined Shuttle Kiln Model DL-54FS |

|

|

|

|

-

Electronic

flame safety, 100% Shut Off

-

Push

button automatic spark ignition

-

Manual

control valve

-

0-15"

water column pressure gauge

-

DD-1

digital, solid state, electronic

controller which functions as a

high-limit, on/off soaking controller

|

|

Note: Two-car

Shuttle Kilns are also available. Specifications

differ in the length overall. Shuttle Kilns

are available in the Natural Draft or Forced

Draft design. Envelope Kilns are also available.

Call GEIL Kilns for details.

|

Specifications

- Fiber Lined Natural Draft Shuttle Kilns (one

car)

| |

GEIL Forced

Draft Kilns

Forced Draft models are the same superior

construction technique as that of the Natural

Draft models, with the exception of the burner

system. A standard Forced Draft system incorporates

the use of an electric blower to force air

through the burners to ensure complete combustion.

Call for specifications and pricing.

|

|

|

|

|

|

|

|